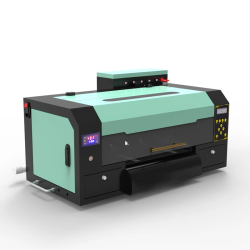

X-4E60 DTF Printer - 24 inch

- Stock: In Stock

- Model: X-4E60

- Weight: 181.00kg

The X-60E DTF printer is a printing machine that can print on various types of fabrics such as cotton, canvas, polyester, blend, nylon, rayon, and rubber materials. It is designed to print on DTF film sheets up to 24" width (60cm), and with its Glorink's smooth and high-quality ink, it can produce fine and vibrant colors.

Equipped with 4 print heads working synchronously, The X-60E DTF printer is allowed to print up to 22 square meters (3900 square feet) per hour on PET film. Additionally, it features a user-friendly interface and low equipment costs while maintaining a high-quality print output.

The X-60E DTF printer is a great choice for those who print frequently, as it has a high printing speed and can handle a large volume of printing with ease. The printer is also beginner-friendly and ideal for those who are just starting in the DTF printing industry.

Overall, the X-60E DTF printer is a reliable and efficient printing machine that produces high-quality prints on various fabrics, making it an excellent investment for businesses or individuals in need of a versatile and durable printer.

Specifications

| Model Number | TT-60E4-K |

| Print head (optional) | I3200-A1 / 4720 |

| Resolution | 2400DPI |

| Speed | 6pass:22 square metter /h 8pass:15 square metter /h |

| Color control | ICC color profile with adjust function |

| Print Width | 600mm |

| Operation Enviroment | Temperature 15-30, Humidity :50%-70% |

| Power | 50Hz/60Hz 110V/220V 10~20A |

| System request | Windows 7 or above |

| Print material | Swimsuit,Diving suit,High-elasticity suit,cotton,Nylon, Chemical fiber, leather, PVC&EVA , etc |

| Image format | Bitmap , Tiff, Jpeg , Eps , Pdf |

| Printer size | 2000*900*1400mm |

| Powder shake machine | 25200*1120*1150 |

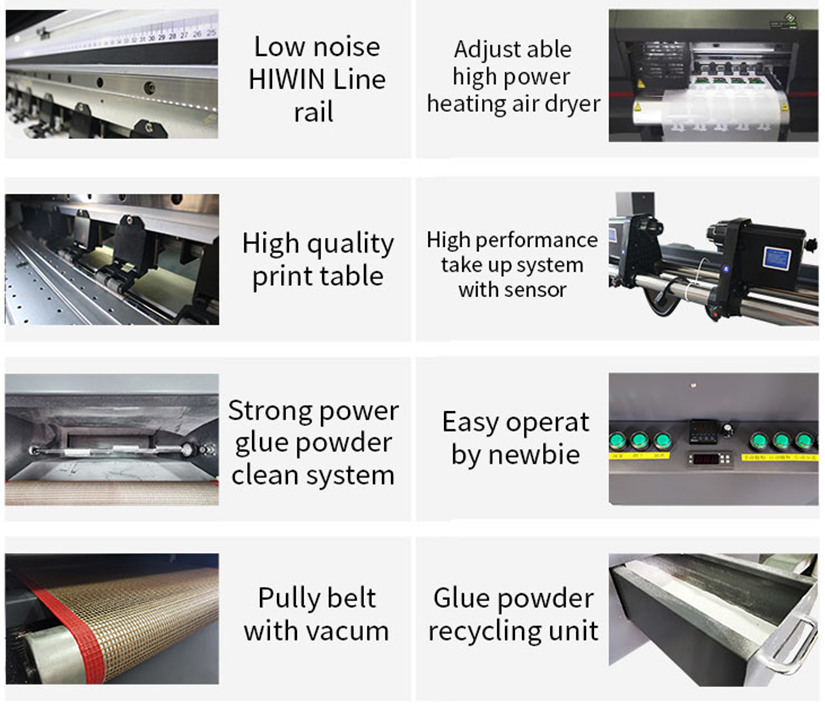

Features

|

DTF Printer |

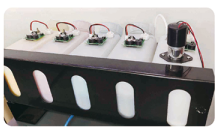

White ink stirring & cycling system |

Tunnel heat curing |

Powder cycling system |

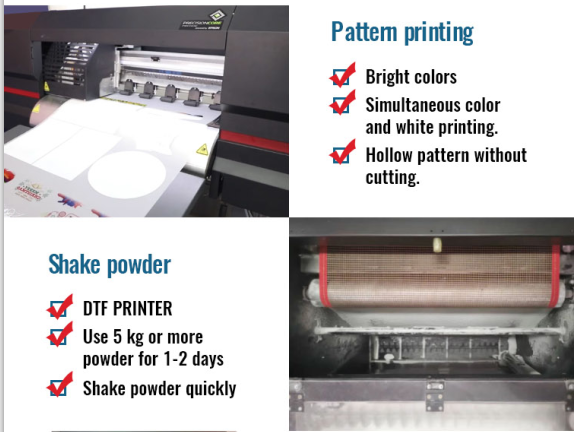

1. DTF printer: Modular made, easy to operate and maintenance. One-click engraving and printing, no need to cut, white ink output at the same time, no need to engrave, efficient and fast. With "any film" technology.

2. White ink stirring & cycling system: Prevents white ink from clogging the nozzle and ensures smooth printing.

3. Tunnel-type baking: Tunnel-type baking system ensures that the PU powder is heated evenly, which can enhance the washing fastness and print in high-quality for heat transfer.

4. Automatic powder shaking machine (aka. Duster): automatic powder spraying, powder shaking, heating, tunnel baking, uniform powder shaking. Automatic powder recycle (to avoid waste & lower production cost), and to reduce the frequency of adding powder. The extended tunnel can match fast printing, and the drying effect is good, preventing the printed patterns from being greasy.

Advantages

1.High productivity

2.Very easy to operate

3.Consistant print quality

4.Print from PC directly

5.Low ink consumption

6.Low waste

7.Suitable for different materials T-shirts

8.No need cutting and peel

9.Good for fastness

How to operate

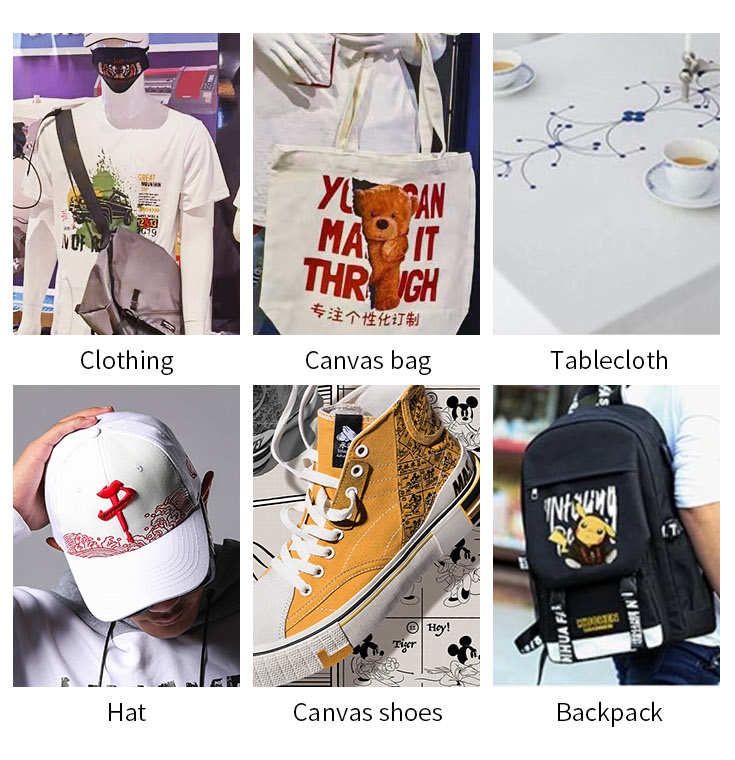

What it can print

Details

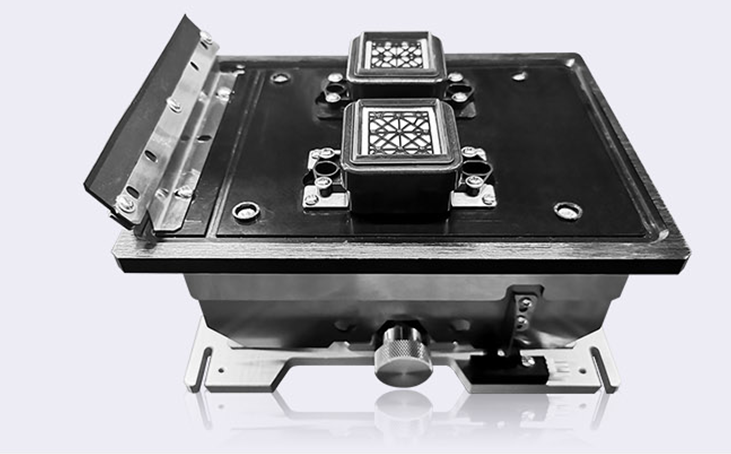

Powder shake machine

Printhead Capping Station (Keep the printheads clean and moistured)

Process Description

-250x250.jpg)

-250x250.jpg)